~From upstream to downstream of manufacturing~

Thank you very much for visiting our web site.

We, Manufacturing System Design Laboratory conduct a wide range of studies on “Digital manufacturing” based on FA & digital techs with broad perspectives from designing/trials to CNC machining centers/mechatronics/ manufacturing systems and process analyses. We contribute to solving social problems such as labor shortages by realizing advanced automation such as creativity design and automation support system, integration of CAD/CAM/CNC machines, and process monitoring/ analysis and numerical simulations.

Feel free to contact us if you are interested in!

News

- Participation in an International Conference Supported by the Keirin and Auto Race Subsidy Program (Research Exchange Support Program for Graduate Students Presenting at International Conferences Held Overseas)

- 8th progress report meeting in FY2025

- 7th progress report meeting in FY2025

- 6th progress report meeting in FY2025

- 5th progress report meeting in FY2025

Research Case Studies

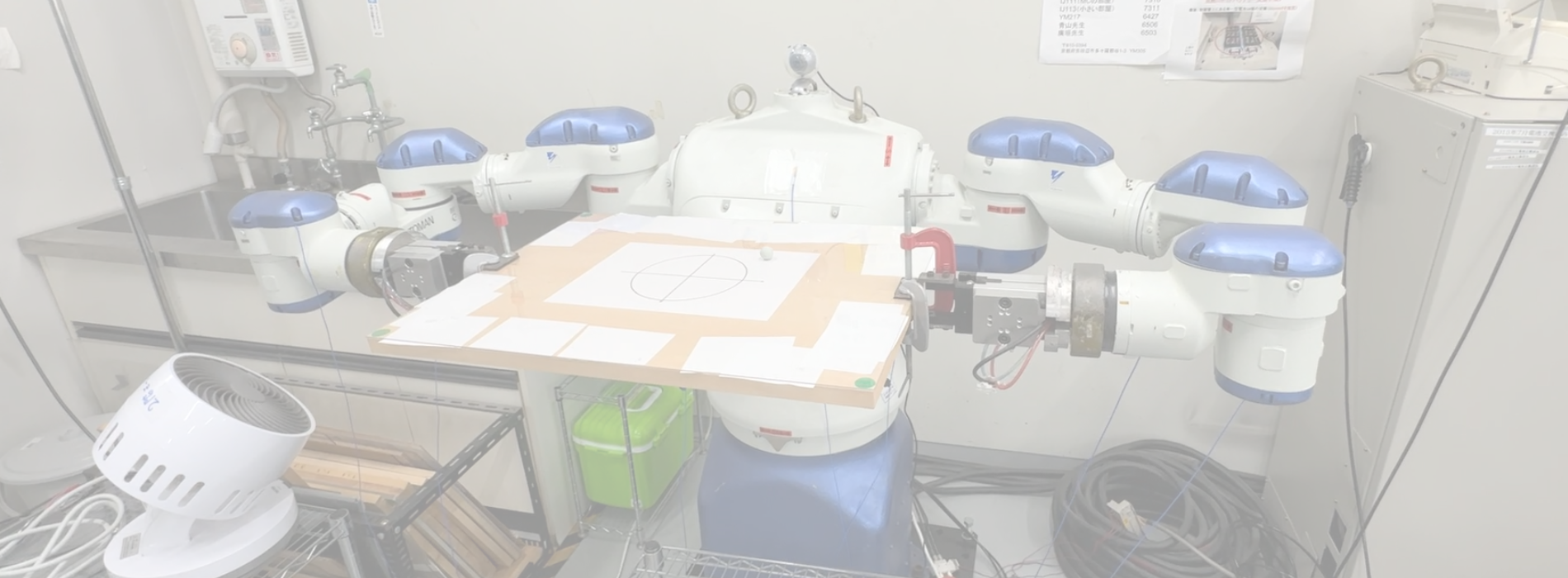

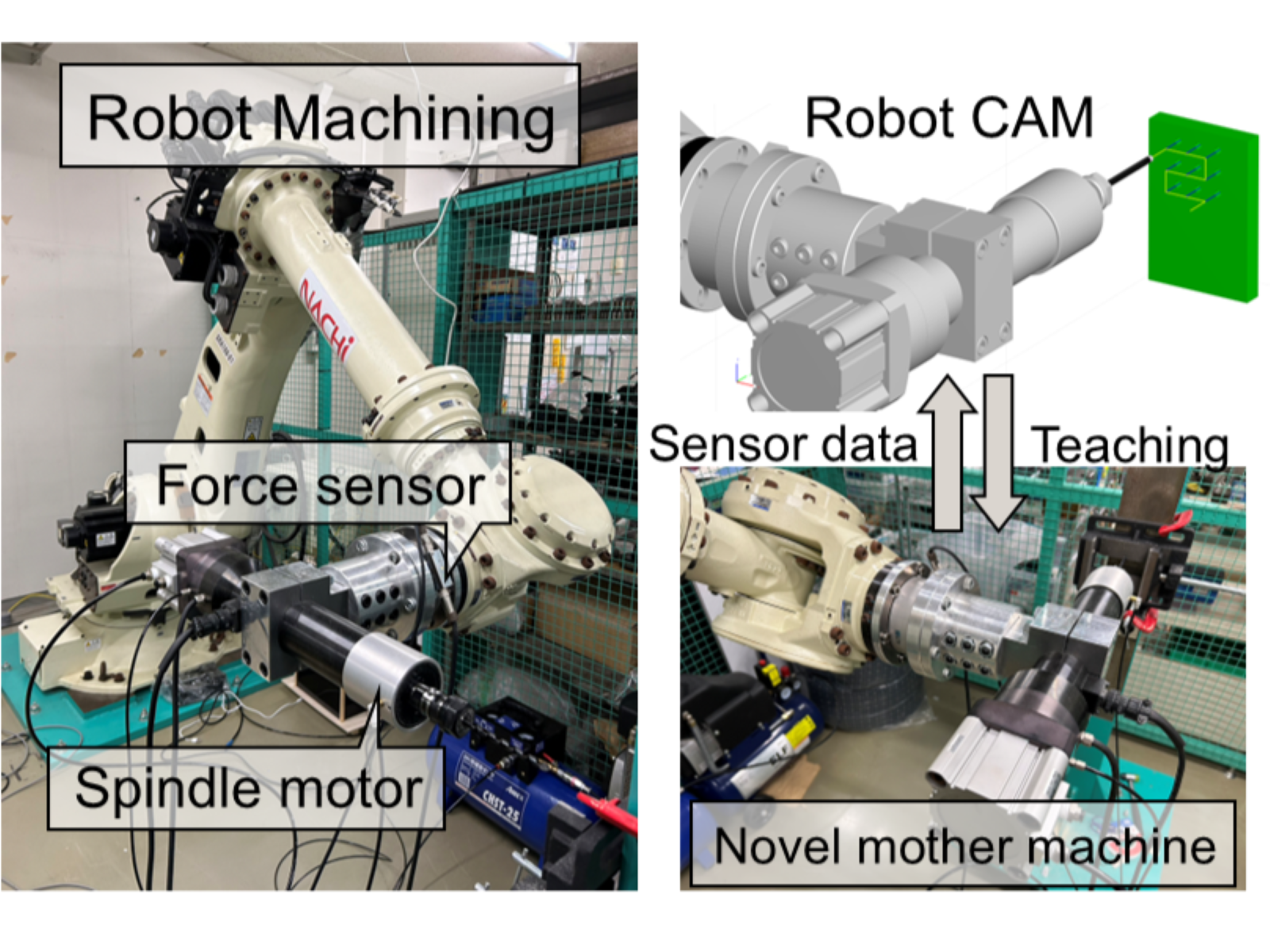

Robot

End milling by a large industrial robot

at a singularity with offline teaching

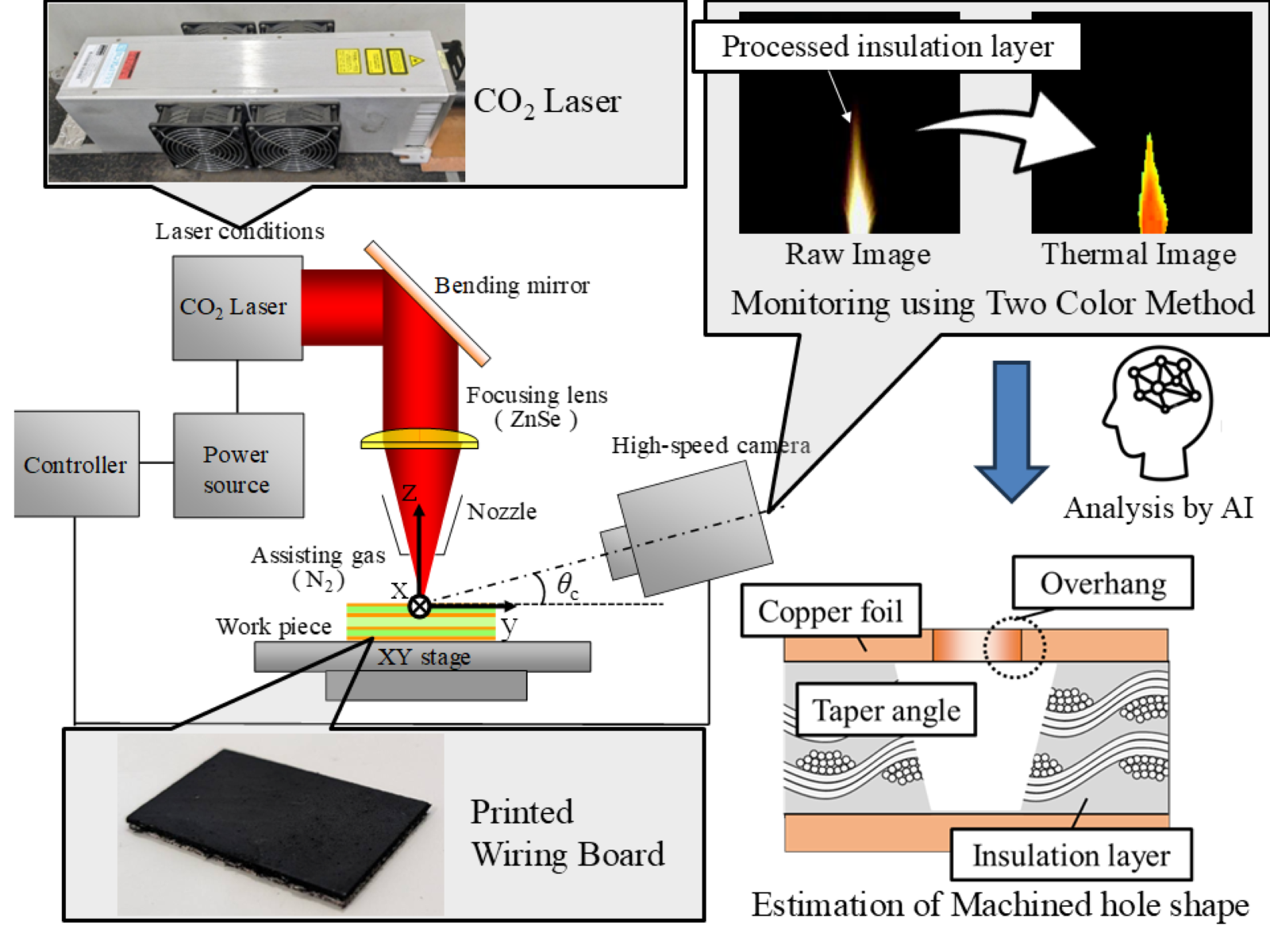

Laser

Construction of a laser processing system for via holes using two-color image processing and AI for digital twin

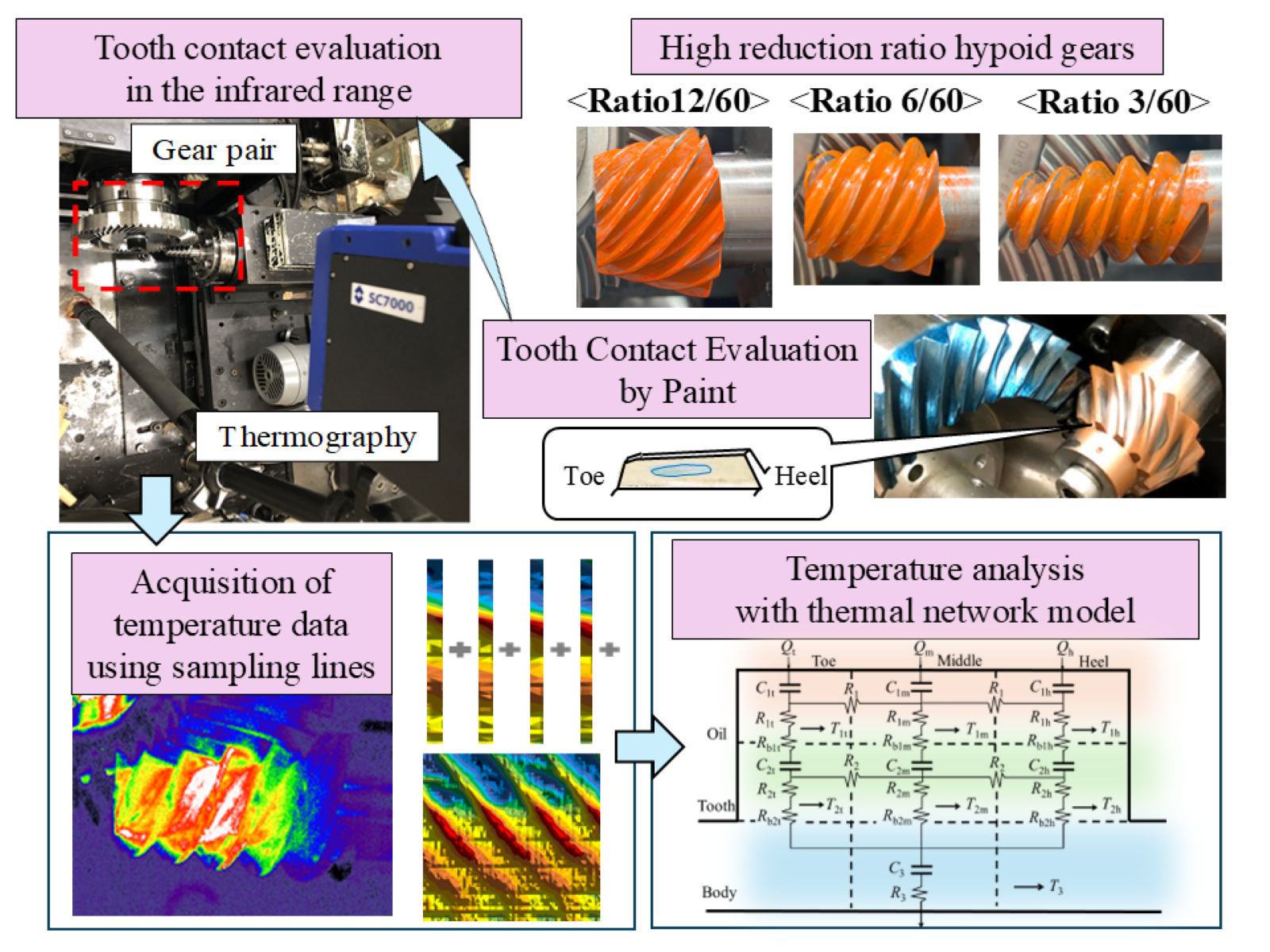

Gear

Investigation of tooth surface temperature based on high-speed thermography monitoring under meshing of hypoid gear with small number of teeth

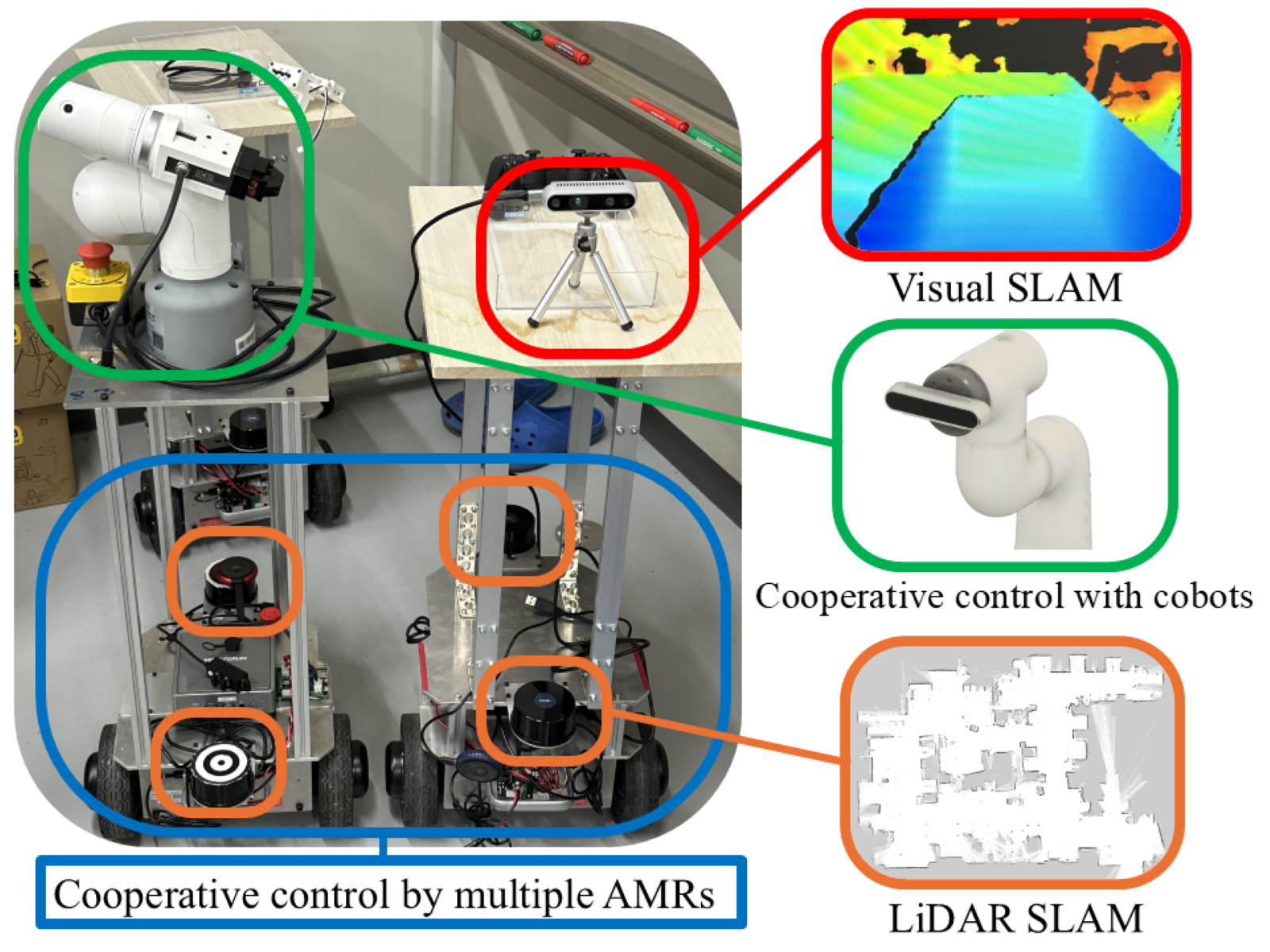

AMR(Autonomous Mobile Robot)

Investigation of LiDAR characteristics and methods to improve motion accuracy in SLAM in an indoor factory for AGVs andAMRs

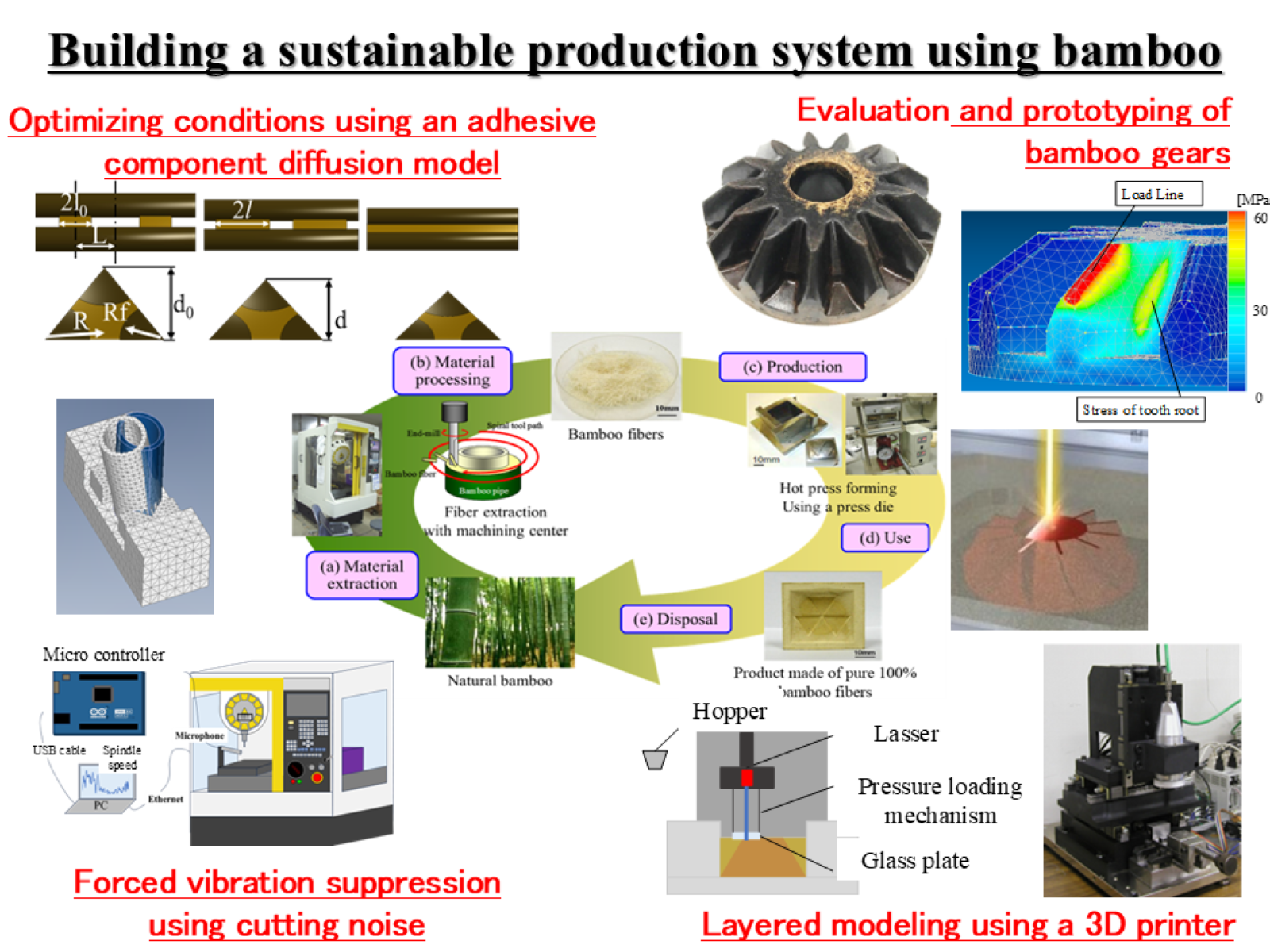

Bamboo material

Constructing a sustainable production system

based on bamboo's self-growth capability

using fine bamboo fibers

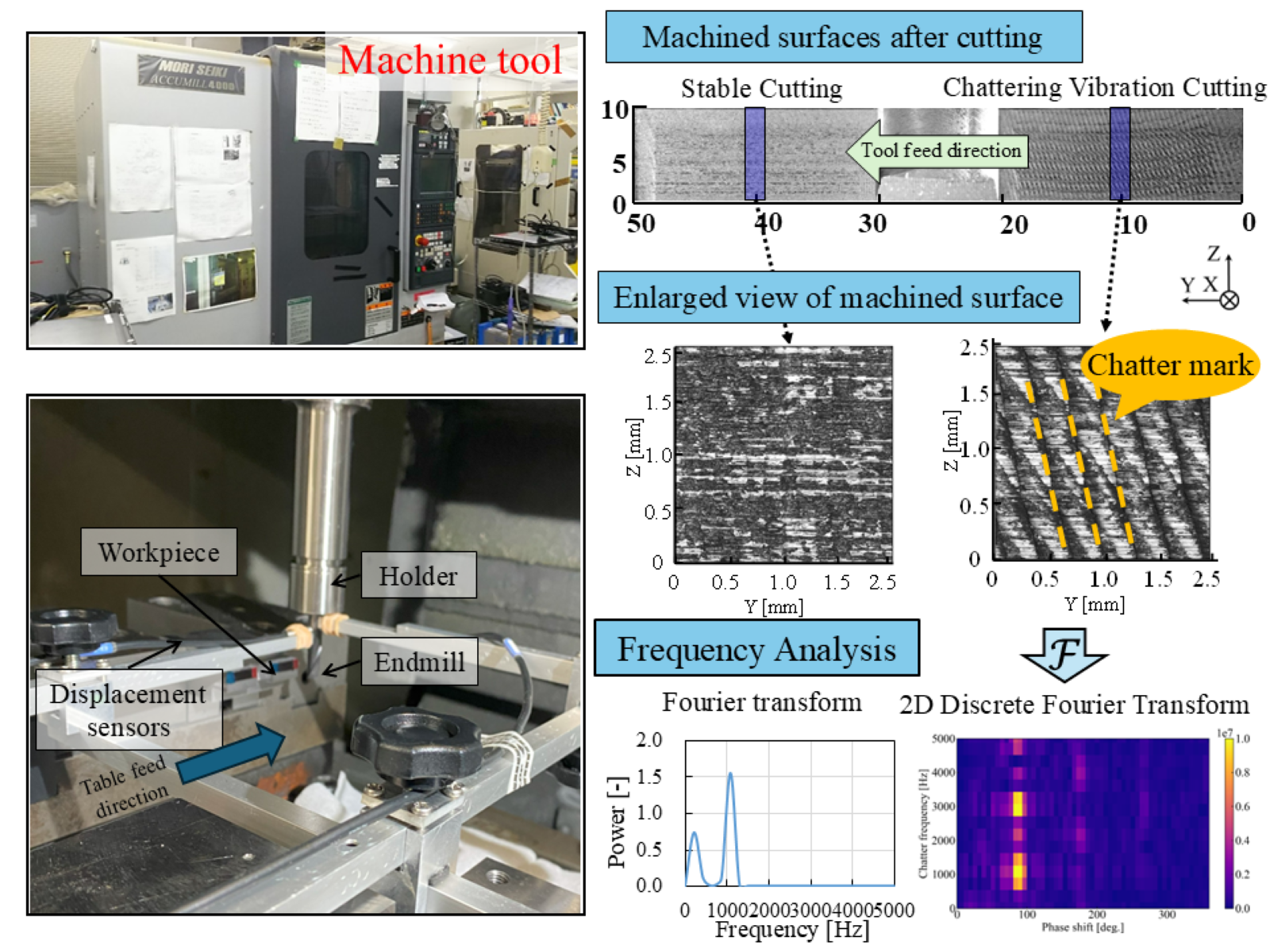

Machine tools

Study on inverse analysis state monitor using

two-dimensional discrete Fourier transform

images of machining surface patterns and chips in end mill chatter vibration of machine tools

Access

Doshisha University

Manufacturing System and Design Laboratory

〒610-0394

1-3 Tatara Miyakodani, Kyotanabe-shi, Kyoto-fu

Yutokukan, East Wing

Room number:YM305・YM217・YM115